GET THE MOST

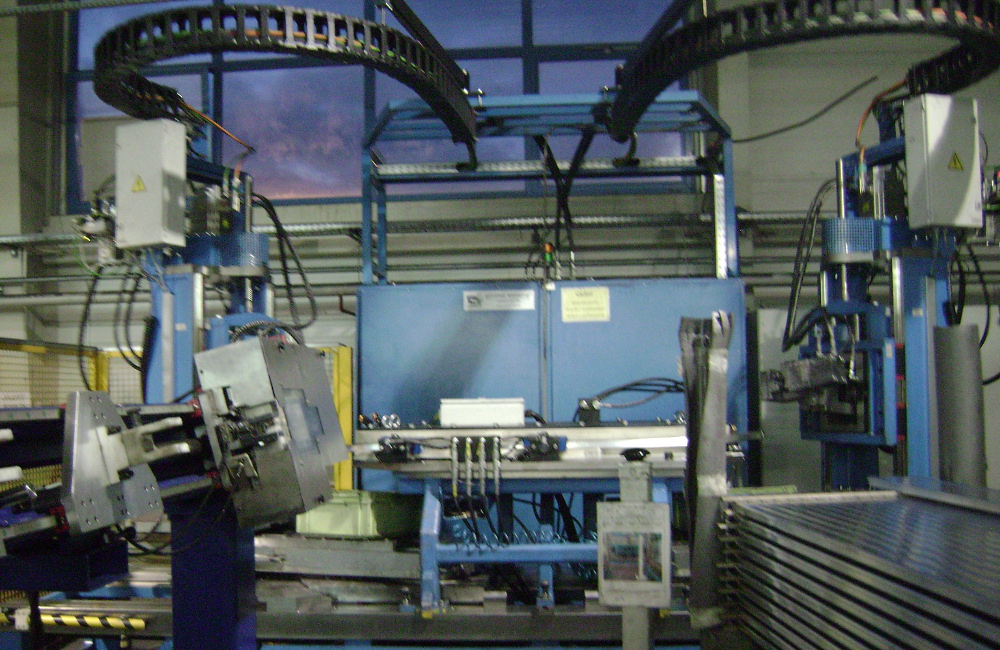

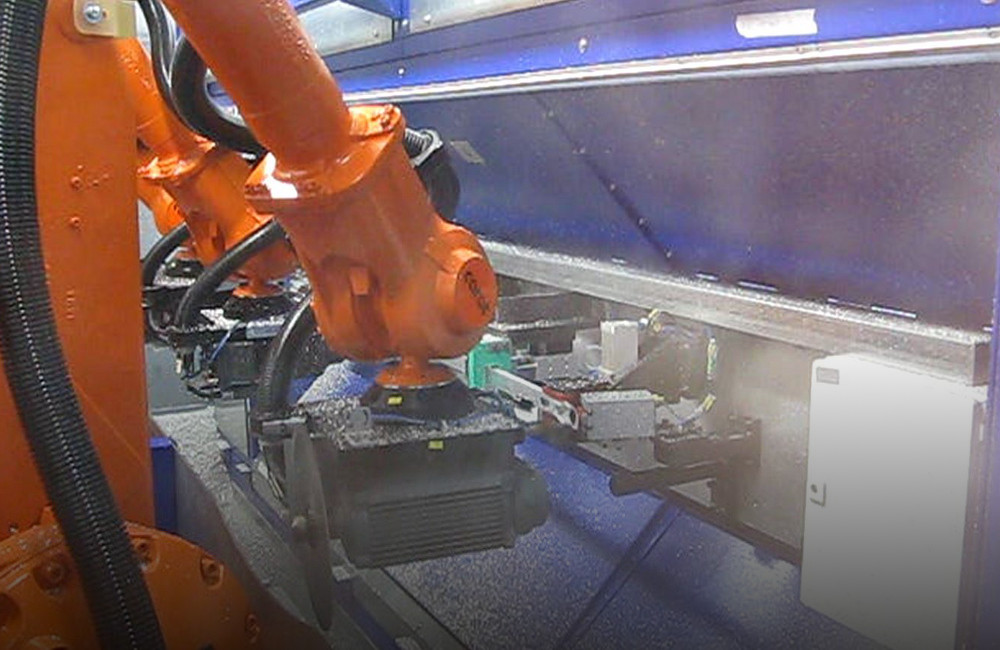

out of your production equipment

with

CHRONOS Downtime Monitoring

BOOST YOUR EFFICIENCY

watch your success

&

with

CHRONOS OEE reporting

REALTIME DATA

right in your hands

available on

Android

iOS